Precision Applied Products

355-B W. Crowther Ave.

Placentia, CA 92870

Get Fused Silica Windows Today!

Fused Silica Windows

We offer stock sizes from 1/8" - 1/4" and 3/8" thick in round sizes from 1/2" up to 5" off the shelf for fast delivery. Fused Silica Windows are High Purity, Chemical Resistant. Extremely Parallel < 2 arc seconds made fast.

Quality

Speed

Cost

Features

- High Purity

- Chemical Resistant

- Extremely Parallel < 2 arc seconds

- Fast Delivery

- Excellent Prices

Fused Silica Window

Fused Silica Window Chemical Composition -This glass consists solely of the amorphous (non-crystalline) type of high-purity silica (SiO2). Other popular glasses, on the other hand such as (Pyrex, borosilicate, soda-lime, etc.) are blended composition glasses they will include components such as Na2O, CaO, and B2O3 in relation to SiO2. These extra components alter the optical and mechanical properties of the glass and reduce the melting temperature of the mixture. On the other hand, Fused Silica is pure SiO2. It has a much greater working and melting temperature than other popular optical lenses and has outstanding optical, thermal and mechanical characteristics.

Fused Silica Windows Chemical Purity

Contaminants have subtle but substantial impacts despite their existence at very small concentrations. The purity of the material, the production process and subsequent processes is mostly determined by the raw material. At all phases of the production method, special precautions need to be taken to preserve high pureness.

Metals (including Al-Na and Fe), water (included in the OH group), and chlorine are the most prevalent impurities. The viscosity, optical absorption and electric characteristics of the glass are affected by such contaminants.

Chemical Compatibility

Fused Silica Window is a highly inert glass because of its sheer structure. The large majority of the chemicals used in laboratories are compliant. Some unusual materials, including HF (hydrofluoric acid) and warm KOH (potassium hydroxide), will attack it.

Thermal Properties

Coefficient of Thermal Expansion (CTE)

Fused Silica has an extremely small heat expansion coefficient, which only differs moderately with temperature.

Fused Silica Windows mean thermal expansion coefficient:

0.52 x 10-6/K over the 5°C to 35°C temperature range

0.57 x 10-6/K over the 0°C to 200°C temperature range

0.48 x 10-6/K over the -100°C to 35°C temperature range

For comparison, INVAR has a mean coefficient of thermal expansion that is more than twice as high as that of fused silica (1,3 x 10-6 ° / K over the 20 ° C to 100 ° C temp range), which has the least thermal expansion of all metals and alloys close to room temperature.

Thermal Conductivity

Fused Silica Window is an outstanding thermal insulator. Its thermal conductivity is only 1.38W / moK (measured at 25oC), which is one of the lowest for any structure. By comparison, this value is 100 % smaller than that of silicon (148W / moK @ 25 C) ; and one eighth of that of INVAR (10.5 W / moK @ 25 C).

Optical Properties

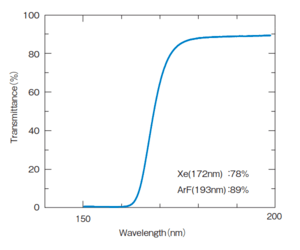

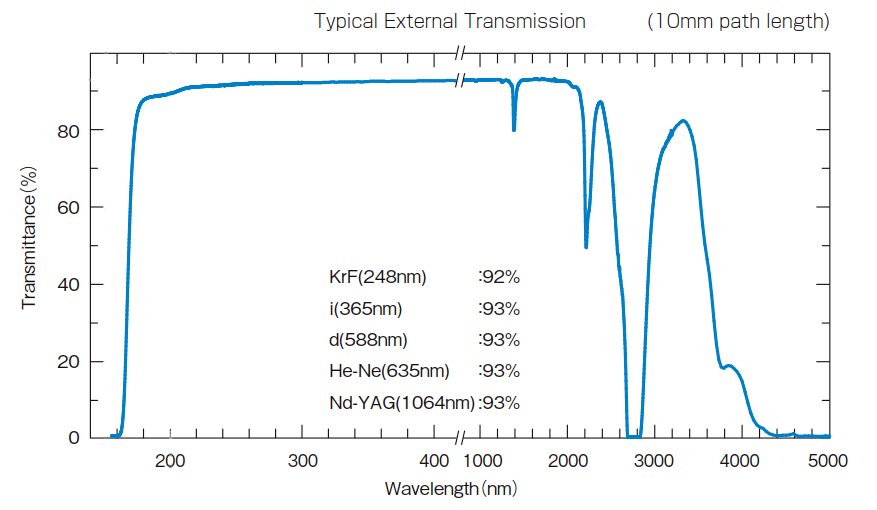

Fused Silica Windows provides a series of optical features which positively compare with other optical materials. From profound ultraviolet (UV) to central infrared. It is transparent.

Optical Absorption

In the ultraviolet, visible and near infrared, Fused Silica Windows are transparent.

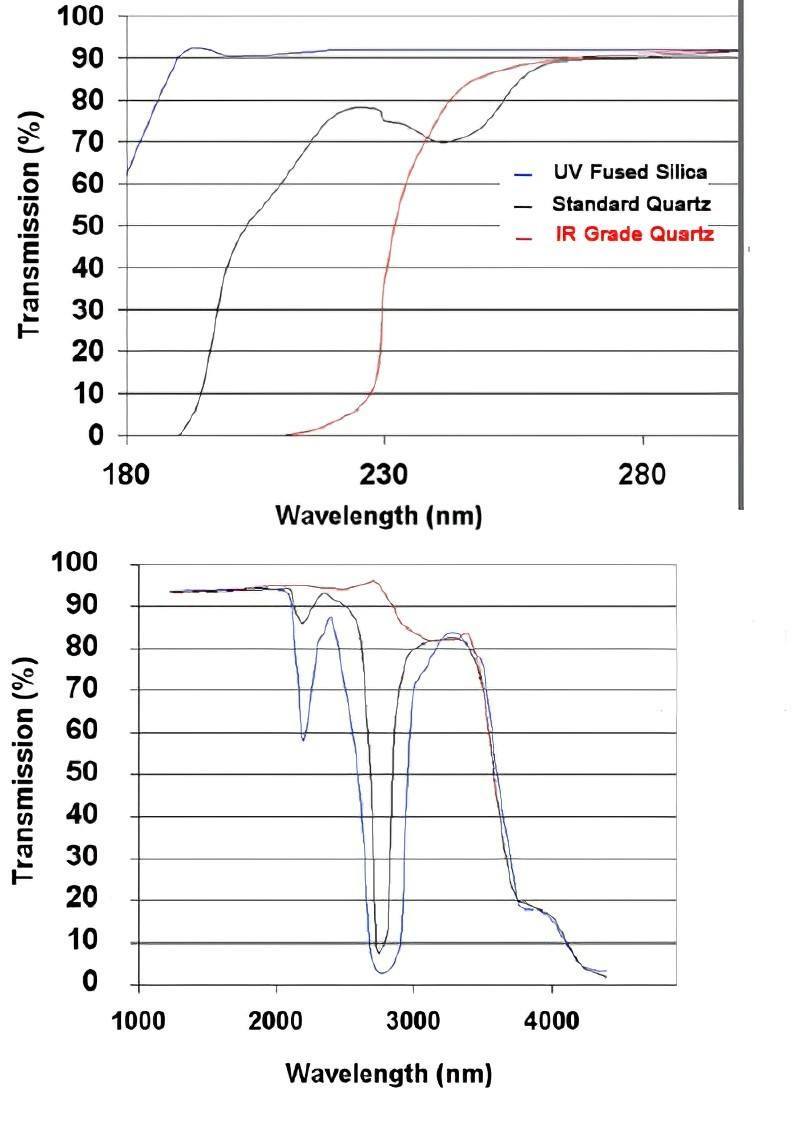

What is the difference between fused silica and quartz?

Fused Silica is a man made product and quartz is a natural product.

Fused Silica is usually more expensive than quartz

Fused Silica will transmit further into the ultra violet than quartz

Quartz has a crystal structure and can be cut along the axis to aid in polarization states.

Quartz can have oxygen content which will increase the infra red transmission.

See the charts below for optical transmission of different materials.

Please note that this is for comparison only, contact our sales staff for your application

and we will suggest a material for your needs.